Lean Manufacturing in Action: Cutting Waste for Cost Savings

Lean manufacturing plays a critical role in helping manufacturers reduce waste, control costs, and stay competitive in an increasingly volatile production environment. In 2026, fluctuating tariffs, geopolitical uncertainty, and evolving environmental regulations continue to challenge manufacturers across the United States. These pressures make efficiency, resilience, and sustainability essential rather than optional.

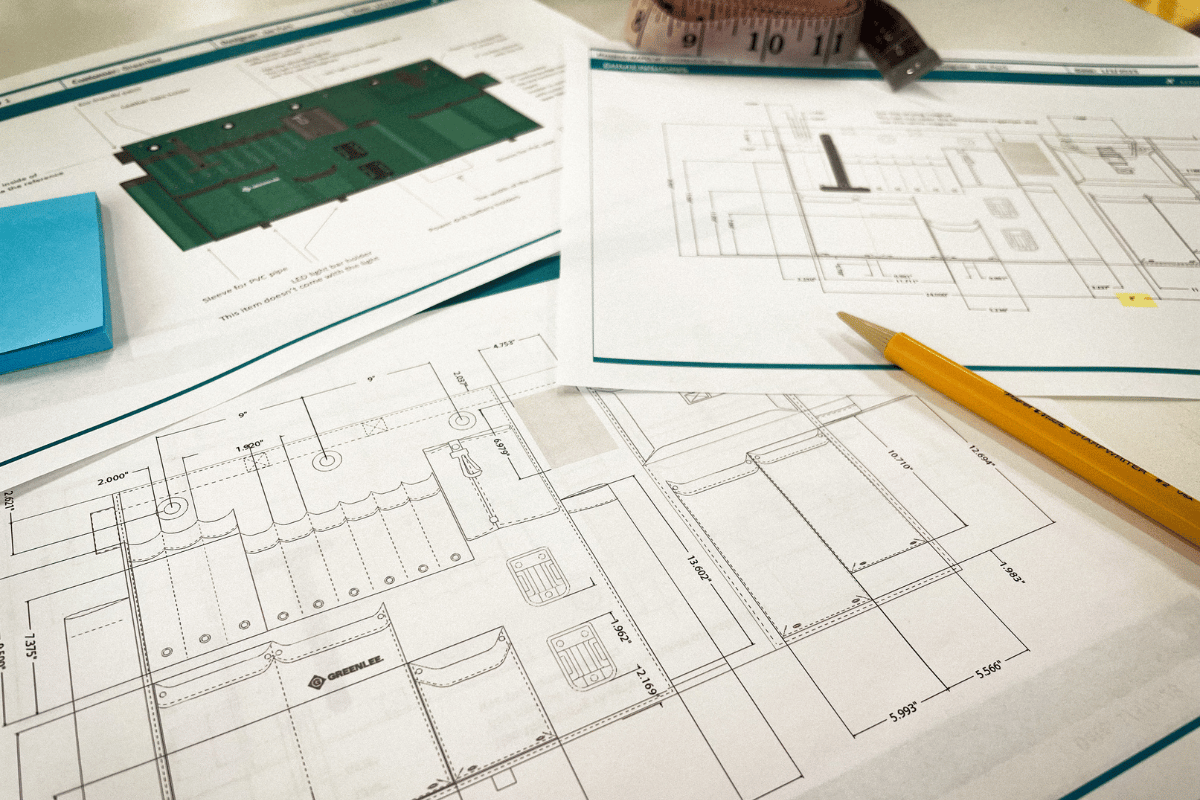

Design for Manufacturability: Smarter Products Start in the Design Phase

Design for manufacturability determines how efficiently and cost-effectively a product can be produced long before manufacturing begins. Across industries, most cost decisions are locked in during the design phase, often before a prototype is built or a single component is produced. This is why design for manufacturability plays such a critical role in successful product development.

Medical Device Packaging: Safe & Sterile Soft Good Solutions

Medical device packaging is no afterthought; it’s a critical guardian of patient safety and product integrity. From the moment they leave the cleanroom, medical devices rely on packaging to keep instruments and implants sterile, secure, and intact. As a matter of fact, experts emphasize that medical packaging is “more than a protective shell—it’s a critical component of product safety, regulatory compliance, and patient outcomes”. As global healthcare demand rises, it has only grown in importance.

Custom Carrying Solutions for Automotive Supply Chains

Automotive supply chains are dealing with an incredibly diverse array of parts, increasing the need for custom carrying solutions. From tiny sensors and spark plugs to large windshields and engines, each with unique shapes, weights, and fragility levels. Standard one-size-fits-all packaging often fails to protect such varied components adequately. This is where custom carrying solutions come into play. By designing packaging and carrying products tailored to each specific part, manufacturers can prevent damage, improve handling efficiency, and optimize space usage during transit.

Bio-Based Plastics: Breakthrough Materials in Custom Products

Bio-based plastics are gaining attention for good reasons, helping U.S. brands reduce their dependence on fossil-based inputs while meeting durability and performance expectations. At the same time, they provide companies with a credible sustainability story to align with reviews, RFPs, and retailer audits.

Sustainable American Manufacturing: Turning Green Practices into Profits

Sustainable American manufacturing is no longer a cost center; it is a strategic asset. In fact, it’s the fastest route to winning market share for brands building in the United States. Buyers and procurement teams now expect lower-footprint products—and proof to support them.

2025 Manufacturing Tariffs: Strategies for American-Based Companies

2025 manufacturing tariffs reshape cost structures and catalyze a decisive wave of reshoring. For producers in the United States, policy volatility translates into opportunity. For one, the rise in domestic production contributes to shorter lead times. Due to the U.S. focus, it also emphasizes stricter compliance. For our American clientele, this enables far closer collaboration. While the headlines promote risk, SI Jacobson Manufacturing channels those into margin, speed, and resilience. This is especially true for soft goods, components, and finished consumer products.

American Reshoring in 2025: The Made-in-USA Manufacturing Boom

The news surrounding American reshoring in 2025 isn’t merely a headline; it’s a recalibration. Companies tired of volatile lead times and fragile supply chains are moving production closer to customers, tightening quality control, and protecting IP. But momentum doesn’t erase constraints. Here’s a clear view of what’s driving the boom, the real-world hurdles, and the practical playbook U.S. manufacturers (and their buyers) can use to win.