Design for Manufacturability: Smarter Products Start in the Design Phase

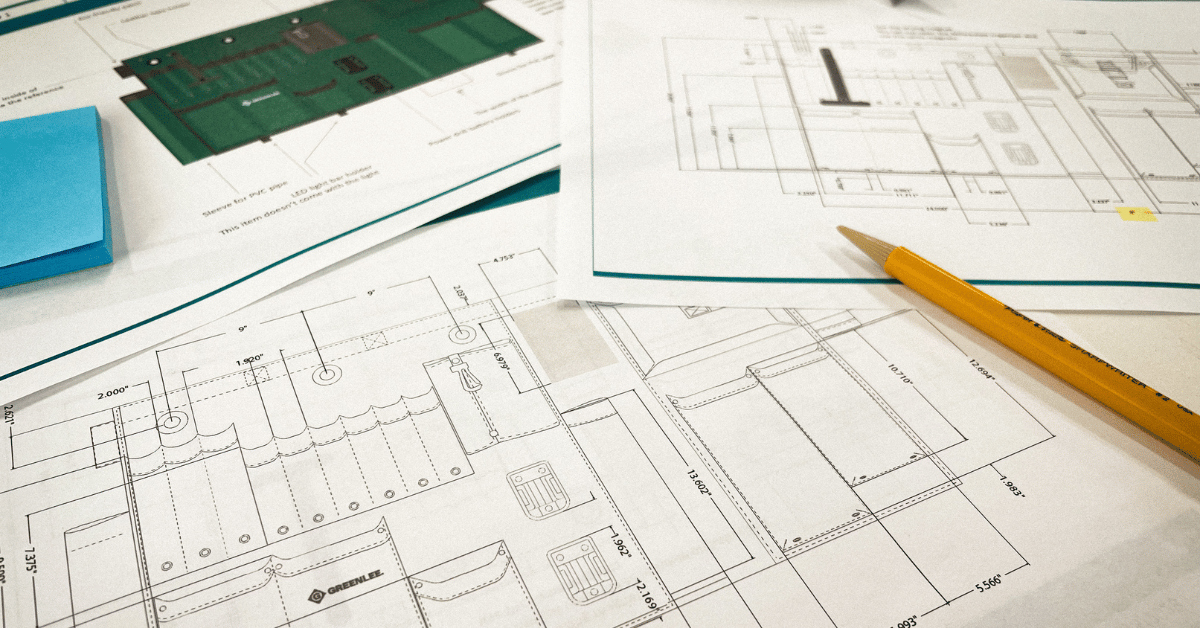

Design for manufacturability determines how efficiently and cost-effectively a product can be produced long before manufacturing begins. Across industries, most cost decisions are locked in during the design phase, often before a prototype is built or a single component is produced. This is why design for manufacturability plays such a critical role in successful product development.

When production realities shape design decisions early, teams avoid costly revisions, reduce waste, and move from concept to production with greater confidence. Products reach the market faster, perform as intended, and scale more predictably. Companies that overlook design for manufacturability often discover problems too late. Redesigns after tooling, sourcing, or production planning introduce delays and unnecessary expense. A disciplined DFM approach prevents these issues by aligning design intent with real-world manufacturing from the start.

What Design for Manufacturability Means in Practice

Design for manufacturability (DFM) is the process of designing products with production efficiency, consistency, and scalability in mind. Instead of treating manufacturing as a downstream step, DFM integrates materials, processes, and equipment constraints directly into the design phase.

For soft goods and sewn products, this approach ensures that what looks good on paper can be built efficiently on the factory floor. Designers account for how materials behave, how parts assemble, and how products move through production lines. When executed well, design for manufacturability reduces friction between design and execution.

Why Design for Manufacturability Is Critical for Soft Goods

Soft goods manufacturing introduces unique challenges. Products such as bags, cases, and protective gear rely on flexible materials, layered construction, and repeated stitching or forming operations. Each design decision affects labor efficiency, material yield, and long-term durability. In fact, research shows that 70% of decisions are made early on in the manufacturing process.

A strong design for manufacturability strategy addresses these variables early, including:

How fabrics and foams perform under load and repeated use

Compatibility with available sewing, forming, and assembly equipment

Pattern layouts that reduce scrap and improve material utilization

Assembly sequences that support speed, consistency, and quality control

By resolving these factors during design, teams avoid production bottlenecks and reduce the risk of late-stage changes.

Core Principles That Drive Better Manufacturability

Effective design for manufacturability focuses on simplicity, consistency, and realistic material selection. Reducing unnecessary complexity lowers labor requirements and minimizes opportunities for error. Standardizing materials and construction methods improves training efficiency and production repeatability.

Material selection also plays a decisive role. A fabric or component may meet performance requirements but still perform poorly in production if it resists sewing, stretching, or forming. Designers who prioritize manufacturability choose materials that balance durability, appearance, and process compatibility.

Production environment matters as well. Designs must align with the capabilities of the facilities that will produce them, whether domestic or international. When designs match equipment, tolerances, and labor workflows, production scales smoothly.

Design for Manufacturability in Real-World Applications

Consider a tool backpack designed for industrial professionals. A design driven solely by aesthetics might specify multiple fabrics, custom-molded components, and complex stitching patterns. While visually appealing, that approach increases cost and complicates production.

A design for manufacturability approach asks practical questions. Can standard die-cut foam replace custom molds? Can heat-transfer graphics achieve the same branding impact as decorative stitching? Can fewer materials deliver the same durability and compliance?

These decisions strengthen the product by making it easier to produce, scale, and maintain consistent quality. The same logic applies to medical carrying systems, industrial storage solutions, and protective packaging across industries.

Applying Design for Manufacturability to Future Products

Design for manufacturability succeeds when designers, engineers, and manufacturing teams collaborate early. Clear communication during concept development allows teams to refine designs before cost and complexity become fixed. When design and production align from the start, products move efficiently through prototyping, validation, and full-scale manufacturing. The result is fewer surprises, predictable timelines, and reliable outcomes for both manufacturers and end users.

Design for manufacturability reduces production risk, shortens time-to-market, and improves overall product quality. It ensures that products meet performance expectations while remaining practical to produce at scale. Brands developing new products or refining existing designs benefit most when manufacturability informs every design decision from the beginning. Without that discipline, production challenges often surface when they are most expensive to fix.

For teams developing soft goods, cases, or industrial products, the SI Jacobson Manufacturing team can help apply design for manufacturability from concept through production. Reach out to start the conversation.