Tool Rolls Reengineered for a New Generation of Industrial Storage

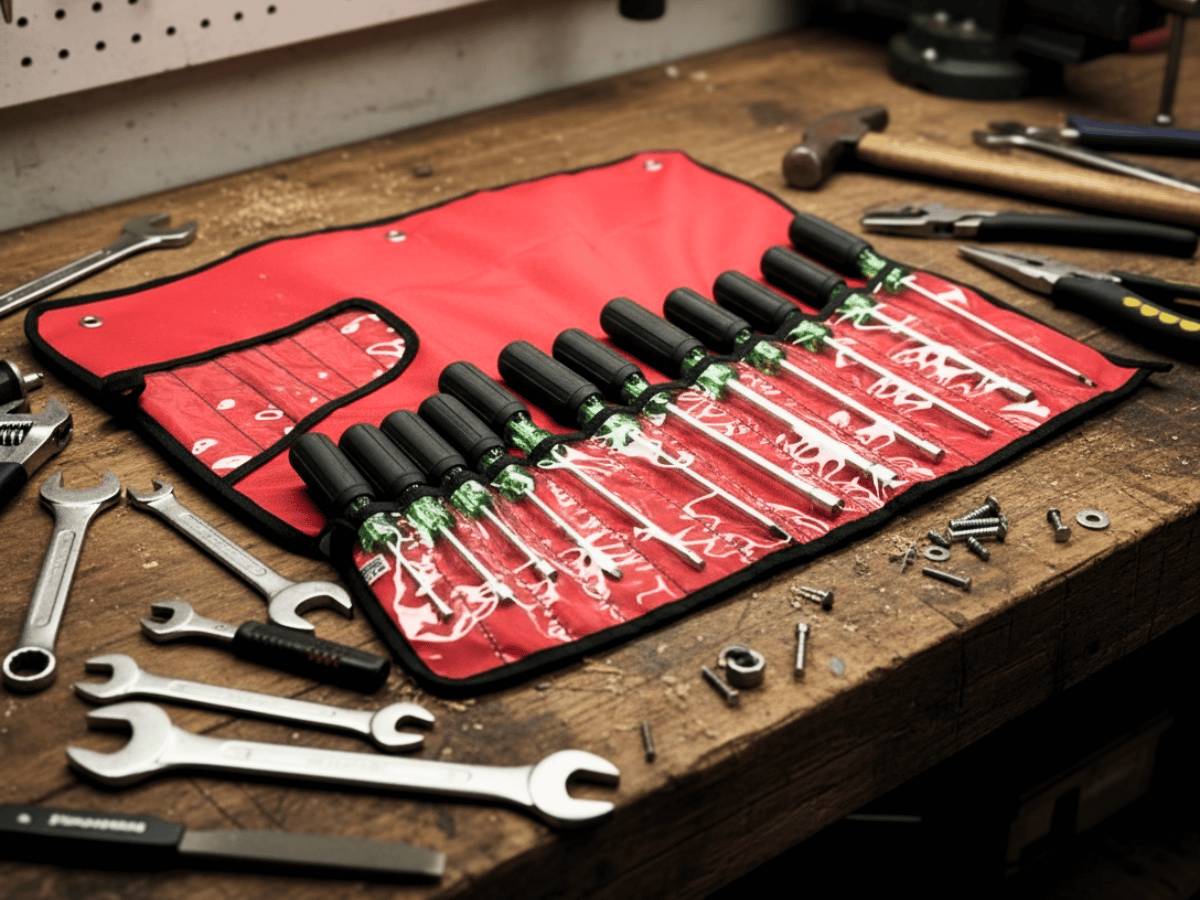

A heritage manufacturer of precision industrial tools partnered with SI Jacobson Manufacturing (SIJ) to redesign its tool rolls and pouches. There was a clear focus on upgrading durability, improving lead times, and refreshing its brand image to resonate with a new generation of end users. As a result, SIJ developed a domestically produced packaging solution that matches the performance of the tools themselves while supporting fast fulfillment and long-term growth.

A heritage manufacturer of precision industrial tools partnered with SI Jacobson Manufacturing (SIJ) to redesign its tool rolls and pouches. There was a clear focus on upgrading durability, improving lead times, and refreshing its brand image to resonate with a new generation of end users. As a result, SIJ developed a domestically produced packaging solution that matches the performance of the tools themselves while supporting fast fulfillment and long-term growth.

Situation: Modernizing Tool Rolls for a Legacy American Precision Tool Brand

Founded in 1927, our customer has built its reputation on producing some of the most durable, high-end precision tools for the industrial and energy markets. Every tool is engineered and manufactured in the United States, and the company prides itself on fulfilling orders within 36 hours. That commitment to speed, quality, and domestic production has long set the brand apart in a highly competitive market.

However, while the tools themselves continued to outperform expectations, the existing tool rolls and pouches were no longer aligned with the brand’s evolving identity. The packaging had served its purpose well, but it lacked the modern aesthetic and refined finish needed to appeal to younger professionals entering the trades. At the same time, the customer faced increasing pressure to shorten lead times and maintain consistent availability without sacrificing quality.

The challenge was clear: Our team needed to modernize the design and performance of the tool rolls while preserving the company’s heritage, meeting strict “Made-in-the-USA” requirements, and supporting rapid fulfillment.

Task: Redesign Tool Rolls to Improve Durability, Lead Times, and Brand Appeal

With a clear vision for where the brand needed to go next, the customer tasked SI Jacobson Manufacturing with redesigning its line of tool rolls and pouches to meet a defined set of strategic and operational goals. The objective was not only to modernize the packaging’s look and feel, but also to ensure every design decision supported performance, speed, and long-term scalability.

The key objectives included:

Refreshing the brand image to appeal to a younger generation of industrial and energy professionals

Ensuring materials and construction reflected the premium quality and precision of the tools themselves

Maintaining or improving durability under heavy daily use and repeated tool insertion

Shortening development and production timelines through domestic manufacturing

Establishing a reliable stocking and fulfillment strategy to support fast order turnaround

All improvements needed to stay within established cost parameters while integrating seamlessly into the customer’s existing sales, distribution, and fulfillment workflows. Above all, the redesigned tool rolls had to reinforce the customer’s Made-in-the-USA commitment while delivering a solution that could grow with demand.

Action: Collaborative Design, Domestic Prototyping & Execution

From day one, SI Jacobson approached the project as a collaborative marriage between design and manufacturing. Our design, sourcing, and engineering teams worked closely with the customer’s product development group to explore multiple concepts for the new tool rolls. Each option was evaluated for material performance, manufacturability, visual impact, and alignment with the customer’s brand values.

Material selection was a critical component of the redesign. After testing several options, the team sourced a durable black denim fabric that delivered both a modern, premium aesthetic and the strength required for heavy industrial tools. The customer’s redesigned logo and updated brand elements were incorporated through custom silkscreening, ensuring crisp, long-lasting graphics that could withstand repeated handling and abrasion.

To accelerate development, SI Jacobson produced multiple prototype iterations at its domestic manufacturing facility. This allowed the customer to review samples quickly, test real-world fit and function, and refine details without the delays typically associated with offshore production. The final tool rolls required a combination of precision sewing, heat-seal applications, and reinforced construction to ensure they could support substantial tool weight without deformation or seam failure.

Beyond design and production, SI Jacobson helped the customer address fulfillment challenges by implementing a tailored stocking program. By maintaining domestic safety stock, the customer could confidently fulfill monthly orders without risking stockouts. This was an essential requirement given their 36-hour fulfillment promise. From materials and components to labor and logistics, sourcing and execution were handled in the United States, reinforcing both companies’ shared commitment to domestic manufacturing.

Result: High-Performance Tool Rolls That Strengthen Brand Identity

The reengineered tool rolls and pouches launched with immediate success. Visually, the updated packaging delivered a premium look and feel that clearly differentiated the brand from competitors. The modern materials and refined branding resonated strongly with younger end users while preserving the trust and familiarity valued by long-time customers.

Functionally, the new tool rolls exceeded durability expectations. Reinforced construction, optimized layouts, and carefully selected materials ensured reliable performance under heavy daily use. Tools remained secure, organized, and protected. This successfully reflected the same engineering standards applied to the tools themselves.

Operationally, the domestic manufacturing and stocking program transformed the customer’s supply chain. Faster development cycles, consistent quality, and on-hand inventory enabled the brand to scale with confidence as demand increased. With highly automated processes and just-in-time delivery capabilities, SI Jacobson became the customer’s preferred domestic manufacturing partner.

Today, these tool rolls stand as a clear example of how thoughtful design collaboration and U.S.-based manufacturing can elevate a supporting product into a strategic advantage. By aligning packaging quality with tool performance, the customer strengthened its brand identity, improved fulfillment reliability, and reinforced its position as a market leader in American-made industrial tools.

When lead times are in question, SI Jacobson Manufacturing can provide the tools your company needs. Learn more about our industrial tools and equipment products or contact our team to start your project today.

Medical Backpack Redesign for IV Therapy Programs

A leading medical device company partnered with SI Jacobson Manufacturing to reimagine its IV pump-carrying program with a next-generation medical backpack designed for safety, efficiency, and real-world clinical use. Serving hospitals and care facilities nationwide, the customer is dedicated to connecting patients and caregivers through life-saving IV therapy products, systems, and services.

A leading medical device company partnered with SI Jacobson Manufacturing to reimagine its IV pump-carrying program with a next-generation medical backpack designed for safety, efficiency, and real-world clinical use. Serving hospitals and care facilities nationwide, the customer is dedicated to connecting patients and caregivers through life-saving IV therapy products, systems, and services.

This company’s mission centers on intuitive, patient-centric design, creating IV solutions that improve clinical workflows while maintaining strict safety and hygiene standards. As IV pump technology advanced and care environments evolved, the customer saw an opportunity to update its existing carry systems to better support nurses, technicians, and caregivers in demanding hospital settings.

SI Jacobson was selected as a manufacturing partner for its deep experience in soft goods engineering, medical-grade materials, and collaborative domestic development. Together, the teams set out to create a medical backpack solution that balanced ergonomics, infection control, durability, and modern design.

Situation: Evolving Clinical Demands Require Smarter Carry Solutions

The customer supplies IV therapy products to hospitals, oncology centers, and critical care environments where speed, accuracy, and cleanliness are essential. Their IV pumps are used daily by healthcare professionals who must move efficiently between patient rooms while managing complex equipment.

However, the existing IV pump carry solutions were beginning to show limitations. Loading and unloading pumps could be time-consuming, access to diagnostics was not always intuitive, and older designs did not fully align with updated hospital hygiene and cleaning protocols. Additionally, caregivers reported discomfort during extended use, particularly when carrying equipment for long periods or across large facilities.

The challenge was compounded by the need to support both single-use and multiple-use applications. Any new medical backpack design had to withstand frequent industrial cleaning, remain compliant with medical standards, and maintain structural integrity after repeated use. Our team needed to achieve this all while offering a more refined, everyday appearance suitable for modern healthcare environments.

Task: Redesign the Medical Backpack for Performance, Hygiene & Comfort

The customer tasked SI Jacobson Manufacturing with updating and advancing its IV pump carry program through a comprehensive redesign. The objective was not simply cosmetic improvement, but a functional evolution that addressed the realities of clinical workflows.

Key requirements included:

Designing a medical backpack that allows faster, more intuitive loading and unloading of IV pump systems

Improving access to pump diagnostics and controls without removing equipment from the bag

Ensuring compliance with updated hygiene standards, including compatibility with industrial washing and cleaning methods

Enhancing ergonomic performance for users of varying sizes and body types

Maintaining a clean, approachable design suitable for everyday hospital use

All solutions needed to meet FDA compliance requirements, support repeated cleaning cycles, and integrate seamlessly into existing hospital environments. The redesign also had to remain scalable, allowing for future updates as IV pump technology continued to evolve.

Action: Collaborative Design & Domestic Prototyping

SI Jacobson’s design and engineering teams worked closely with the customer’s product development and clinical stakeholders to understand real-world use cases. Early discovery sessions focused on how nurses and technicians interact with IV pumps during transport, setup, and monitoring.

From there, SI Jacobson developed multiple medical backpack concepts that prioritized accessibility, protection, and ease of use. A new identification and orientation system was introduced to guide faster pump loading and ensure correct positioning every time. Strategic access points allowed caregivers to view diagnostics, manage tubing, and monitor performance without removing the pump from the backpack.

Material selection played a critical role. SI Jacobson sourced FDA-compliant textiles and components engineered to withstand more than 25 industrial wash cycles without degradation. These materials balanced durability with flexibility, ensuring the backpack remained lightweight and comfortable while protecting sensitive medical equipment.

Ergonomics was refined through adjustable carry systems designed to accommodate a wide range of users. Load distribution was carefully engineered to maintain proper weight balance, reducing strain during extended use. Domestic prototyping enabled rapid iteration, allowing the teams to test, refine, and validate designs quickly while incorporating direct feedback from clinical users.

Result: A New Standard for Medical Backpack Performance

The redesigned medical backpack was launched successfully and quickly set a new benchmark for hospital acceptance and user satisfaction. Nurses and technicians reported faster setup times, easier access to diagnostics, and greater confidence in the security of equipment during transport.

The ergonomic improvements reduced fatigue, while the upgraded materials and construction supported rigorous cleaning protocols required in modern healthcare settings. Most importantly, the backpack design aligned seamlessly with the customer’s patient-centric philosophy.

SI Jacobson continues to support the customer with ongoing updates and refinements as IV pump technology advances. Through a collaborative, domestic manufacturing approach, the partnership delivers reliable, compliant, and scalable solutions that evolve alongside the needs of healthcare providers.

This case study demonstrates how thoughtful design, material expertise, and disciplined execution can transform a medical backpack into a critical component of modern IV therapy programs, improving outcomes for caregivers and patients alike.

Your healthcare team should have medically compliant equipment readily available for clinical use. Learn more about our medical and healthcare product services or contact our team to start your project today.

Rope Storage Bag Redesign

A leading forestry equipment supplier partnered with SI Jacobson Manufacturing on a comprehensive rope storage bag redesign to improve durability, safety, and reliability for professional field crews. The existing design, though proven, was showing wear under heavy daily use. This prompted the need for stronger materials and construction without raising production costs. SI Jacobson’s design and sourcing teams re-engineered the bag from the inside out, reinforcing critical seams and high-stress points while maintaining efficiency across manufacturing lines. The result? A stronger, longer-lasting product that now performs dependably in the toughest forestry environments.

A leading forestry equipment supplier partnered with SI Jacobson Manufacturing on a comprehensive rope storage bag redesign to improve durability, safety, and reliability for professional field crews. The existing design, though proven, was showing wear under heavy daily use. This prompted the need for stronger materials and construction without raising production costs.

SI Jacobson’s design and sourcing teams re-engineered the bag from the inside out, reinforcing critical seams and high-stress points while maintaining efficiency across manufacturing lines. The result? A stronger, longer-lasting product that now performs dependably in the toughest forestry environments.

Situation: Rope Storage Bags Facing Premature Wear

The client’s original rope storage bag was a core product for its customer base of professional arborists and forestry crews. These users often work in remote, rugged areas where dependable gear is critical to both efficiency and safety. However, the bag’s seams and load-bearing areas were prone to premature wear, especially when subjected to repeated drops, moisture, and abrasive materials.

The issue wasn’t limited to one defect; it was a combination of material fatigue and structural strain over time. Our client needed an upgrade that could withstand years of heavy use while preserving the recognizable look and accessibility features valued by users.

Task: Improve Rope Bag Durability & Load Performance

The client tasked SI Jacobson with redesigning the bag to deliver maximum durability, improved load capacity, and stronger seam performance. All of these components needed to fall within the client’s existing price and production parameters.

For this process, the challenge lay in balancing engineering precision with cost efficiency. This included sourcing new materials, improving construction methods, and ensuring that every change could integrate seamlessly into existing manufacturing systems. Overall, the objective was not to reinvent the bag but to evolve it, preserving its brand identity and significantly extending its field life.

Action: Engineering-Driven Material Selection & Reinforced Construction

SI Jacobson’s design, sourcing, and engineering teams conducted a complete teardown and performance audit of the existing bag. Using real-world load simulations, we identified the stress points where the product was most vulnerable. From there, multiple prototype iterations were developed, incorporating advanced textiles with superior tear resistance and water repellency. Reinforced stitching patterns, bar-tacked stress points, and optimized seam alignment were tested under controlled conditions to validate long-term durability.

Throughout the process, SI Jacobson collaborated directly with the client’s product team to review samples, compare materials, and align each modification with end-user feedback. Once the SIJ team finalized the enhancements, our global manufacturing network ensured a seamless transition into full production, maintaining efficiency, consistency, and quality control across every unit.

Result: Longer-Lasting Rope Storage Bags That Improve Crew Safety

The re-engineered rope storage bag exceeded performance benchmarks in both strength and field testing. By addressing the root causes of seam fatigue and structural failure, SI Jacobson delivered a more dependable, longer-lasting product that reinforced the client’s reputation for quality in the forestry and arborist markets. The bag now offers enhanced stability under load, better weather resistance, and improved ergonomic handling. Every rope, tool, and piece of equipment is stored safely on the job.

Today, this rope bag line stands as proof of how thoughtful design collaboration and technical manufacturing expertise can turn a simple product upgrade into a measurable advantage in reliability, brand reputation, and user trust.

Your team should be able to depend on storage equipment for the long term. Learn more about our consumer and outdoor product services or contact our team to start your project today.

Refreshed Bag Design For Tool Line

A top-tier industrial tool manufacturer needed its professional tool bags to better reflect its premium brand. SI Jacobson collaborated on new designs, integrating the client’s corporate identity and rugged materials for durability and style. The reimagined line launched successfully, boosting brand recognition and securing placement in major retail outlets. This solidified their position in the professional trade market.

A top-tier industrial tool manufacturer needed its professional tool bags to better reflect its premium brand. SI Jacobson collaborated on new designs, integrating the client’s corporate identity and rugged materials for durability and style. The reimagined line launched successfully, boosting brand recognition and securing placement in major retail outlets. This solidified their position in the professional trade market.

Situation: Professional Tool Bags Falling Short of Industrial Brand Standard

A leading manufacturer of industrial tools, serving technicians and tradesmen across the electrical, construction, and aerospace industries, needed to strengthen its professional tool bag line. Despite offering premium tools and equipment, their existing tool bags failed to reflect the same level of quality or stand out in a crowded market.

Task: Redesign Industrial Tool Bags to Elevate Job Functionality

The client’s goal was clear: redesign their tool bag portfolio to better align with their premium brand positioning. They wanted products that not only looked and felt superior but also highlighted the functionality and storage systems professionals demand on the job.

Action: Integrate Corporate Identity, Rugged Materials & Functional Design

SI Jacobson collaborated closely with the client’s product management team to bring the new corporate identity into every detail of the tool bag line. Our design team developed multiple concepts, while our development team selected durable, rugged materials that would withstand demanding conditions. From improved aesthetics to reinforced performance features, we created a signature, differentiated look and ensured flawless execution through our U.S. and global factories.

Result: Premium Tool Bags That Boost Brand Recognition

The reimagined product line successfully launched, establishing a bold brand identity that matched the quality of the client’s tools. The redesign not only elevated their presence in the professional trade market but also unlocked new opportunities. Most notably, this bag contributed to the placement of a flagship item in a major big-box retailer. This expansion solidified the client’s premium positioning and created a platform for future growth.

Your tools deserve cases and accessories that work as hard as they do. Learn more about our industrial manufacturing services or contact our team to start your project today.